Ever-evolving to adapt to consumer needs, Cellofoam North America Inc. ("Cellofoam") applies its decades-long experience as an industry leader to serve as a trusted partner to all its customers. We understand that many consumers and businesses who use our products depend on practical, effective and cost-friendly solutions, and we produce exceptional products and services that protect what matters most to them.

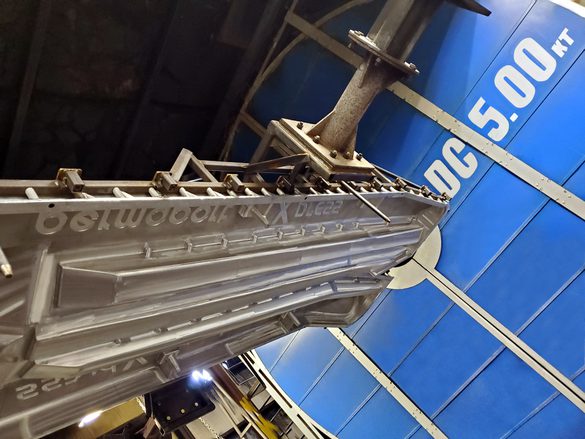

Cellofoam offers a diversified line of commercial, residential and industrial products, including building materials, custom rotational molding, packaging, and marine products like floats and ports. Further, we take our responsibility toward environmental protection seriously, instituting sustainable energy practices in manufacturing and employing recycled materials in the production of Expanded Polystyrene (EPS) insulation and packaging materials.

With 14 manufacturing, design and testing facilities throughout North America, Cellofoam has been an industry leader in building products and industrial packaging since 1979, trusted by major retailers like Home Depot. Thanks to rigorous research and development, our marine floats and ports have become leading consumer solutions for docks, and our products guide the industry in environmental sustainability.

Since our inception, Cellofoam has differentiated itself through a commitment to customer service and a responsibility to forge practical, effective, sustainable, and cost-friendly solutions for its customers.

We’re dedicated to manufacturing products that meet the highest standards of quality and performance. Need to know if Cellofoam’s products are right for your next project? Reach out to our team.